I started using this clutch six years ago and it was a NOS clutch assembly that I bought from a guy in Singapore. I never fitted the stock frictions and steels that came with it. Instead I fitted a 15 plate H2 Barnett kit. I probably have at least 30K miles on this clutch now.

To my knowledge this is the only way to get a 15 plate clutch in a H1.

Here are some pictures I took during the inspection.

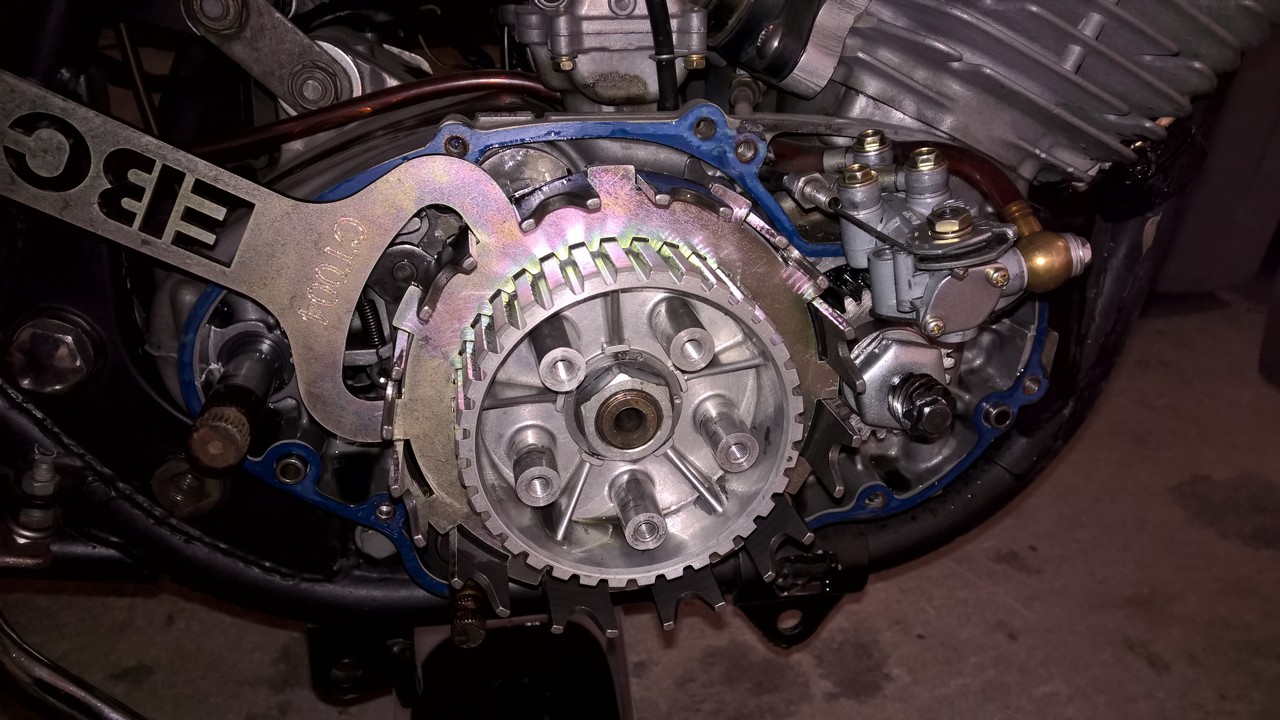

Finally I got to play with my EBC clutch tool.

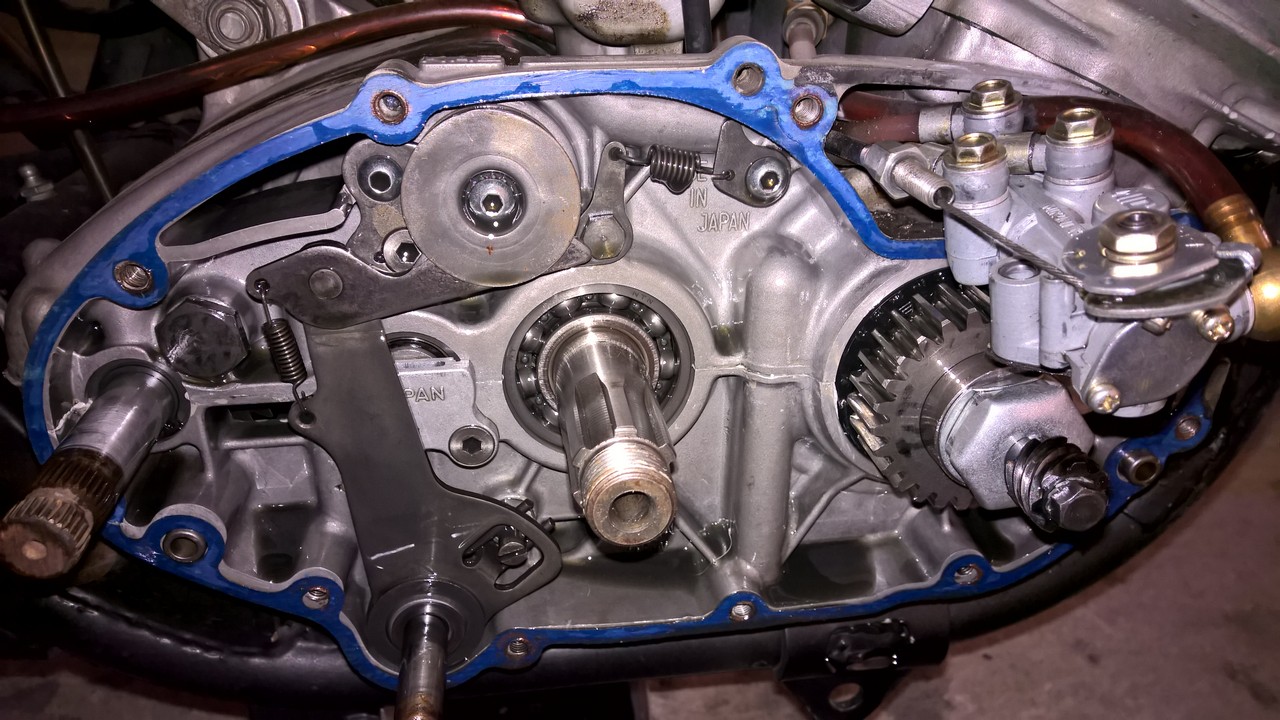

Everything looks to be in perfect condition. I was especially interested in the input shaft tranny bearing. This bearing has failed on me once before and it wasn't a pretty sight.

No problems here.

The oil looks a bit dark. Maybe I should change more often. Up till now I have changed the oil at the start of every riding season which may be up to 6K miles.

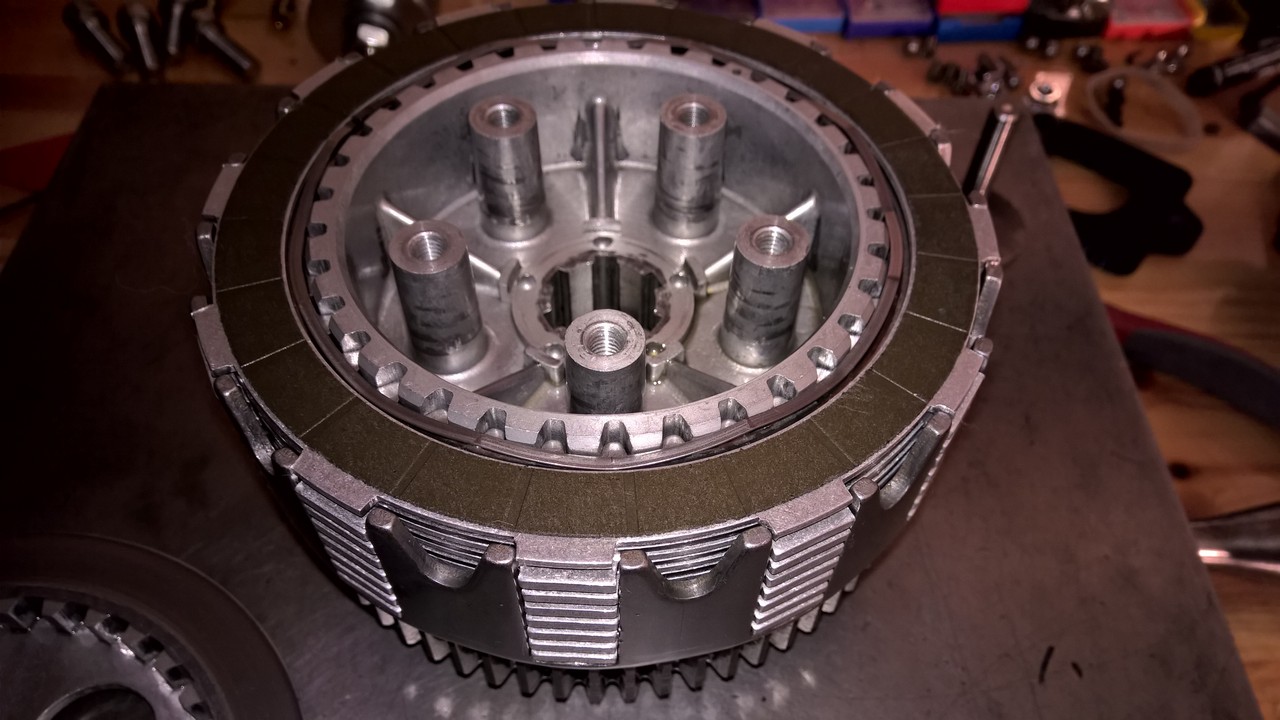

The washer between the hub and basket has been precision ground down from 2.5mm to 2.0mm. This is instead of machining off the hub.

The thickness of the frictions are 2.7mm. I believe this is about the same as stock H1, or maybe a tad thinner.

The greenish color is because they are made of Kevlar.

The thickness of the steels are 1.3mm. Significantly thinner than stock H1 which is 1.6mm

No bluing on any of the steels. Surprisingly little wear for ~30K miles.

Not much left of the hub when all the plates are in. The mesh between the splines in the hub and the pressure plate is less than 2mm when the plate is in the outer position and probably 4.5 - 5.0mm when fully engaged.

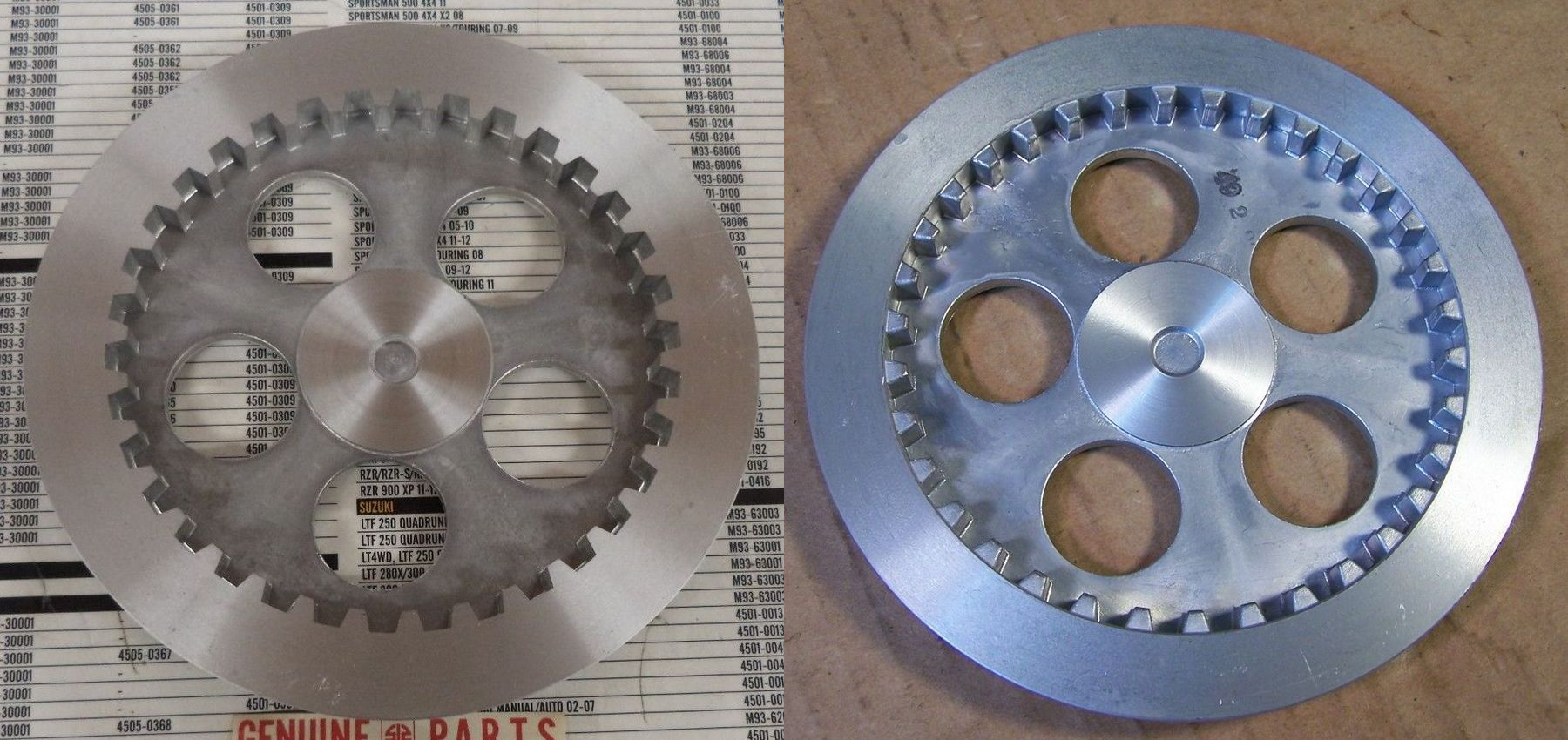

There are two different aluminum pressure plates, one is flat and the other has a step between the splines and the friction face. I use the flat version to maximize the mesh with the hub.

Not much room between the pressure plate and the cover. Had to grind away a casting mark that was interfering with the pressure plate when pulling the clutch all the way.

.