2-Stroke Technology, -a brief explanation

Over the

last few years, I have done about 1000 dyno tests of triples alone, and the 750

in particular, trying to make them powerful at all revs.

Back in the days,

very powerful triples were made, but often at the expense of power below

powerband, and especially low end power in the idle-4000 rpm area.

Today, we

have new made, good pipes as Jollymoto and Jim Lomas

race, with a 108mm belly that produce good power. Old school pipes like Denco, TNT, Figaroli and others,

also produce decent power, but cannot match the newer design pipes mentioned

above.

When I

started dynoing our beloved triples, it was consensus

that VM34’s is the optimum carb size, and that big carbs such as VM38 or 38 flatslides is not a good solution, killing low end. In

fact, 34’s are a quite small carb for a 250cc old piston port. They do,

however, work GREAT for milder applications where an 80-90 rwhp engine is the

target.

Earlier, it

was common to increase inlet duration being able to get great peak power

figures. That works very well. BUT…..at the expense of low end power.

That is due

to the piston pumping ability decrease, and you also get more reversion through

the carbs. A 2 stroke without reeds are a very bad pumping device, as it only

pumps from inlet closing, to transfers opening. When in powerband however, you

are not dependant on piston pumping as your engine no longer works as a pumping

device like the fourstrokes, but as a resonator. It

is the vacuum produced by the pipes that draws up the fresh charge, not the

piston that pumps it. That’s why increased inlet duration gains power in

powerband, but loose at lower revs.

In the

midrange (I call midrange 4-5500 rpm area) the pipes vacuum starts to work, and

at some rpm the transition occurs. (Where the vacuum is greater for flow than

the pumping). I believe that point is in the 4500 area, depending on the pipes.

It is seen

that instead of compensating for small carbs by increasing inlet duration, you

can simply put on larger carbs. And have about same power increase in powerband

as a smaller carb set-up with a 5mm piston skirt cut out. BUT, since you do not

loose piston pumping, low end does not suffer even if powerband becomes

stronger, as seen on old set-ups.

Neville Lush

came up with a 1,5mm cylinder lift and the usage of 38mm carbs many years ago.

Once I investigated that further, I immediately literally blow the 100 rwhp target, without losing much power below powerband.

The

advantage by raising the cylinders by adding a 2mm copper or aluminum gasket is

several. You increase transfer duration to 126-ish degrees without doing any

portwork at all. You can increase exhaust duration to 185-ish, and maintain the

piston pumping ability. You will also increase crankcase volume, which is good

as you have more “space” for the incoming charge, AND you make the life easier

for the pipes as they become more able to suck up fresh charge due to the

increased volume. That means, you gain power, and sooner with the pipes being

able to suck up fresh charge, AND they suck up more, especially in powerband. I

don’t know the significance of the increased volume though.

When raising

cylinders though, your blowdown phase decreases due to the geometrical aspects.

But there is a simple solution to this.

You increase

blowdown, not necessarily by raising the exhaust further than the cylinder lift

itself provides, but by widening the ex ports. The

upper part of the port is the critical area, as it is open at a longer time

than the lower part of port.

So, coming

up with a blowdown number in duration only, does not make sense. We use angle

area instead (a 30 degree blowdown using a square ex port

70% of bore chordial width, gives a LOT more

effective blowdown than just 30 degrees by using stock exhaust port shape).

What happens

when you increase blowdown the old way, by using stock profile but a higher ex port?

You lose

power stroke, and, dependent of how much raise, you do not increase angle area

versus a 70% square port with a LOT less exhaust duration.

So. It is a

win, win using this port shape: You increase blowdown, and also keep more of

the power stroke. That is another reason for better low end power.

But what

happens inside engine when blowdown is increased?

-Blowdown is

probably the most important single factor for more power on a port work phase.

The reason for that is you lower the pressure inside cylinder, and at the time

the transfers open, the decreased pressure versus the crankcase pressure makes

flow up transfers better. The higher the rpm and throttle

opening, the higher the pressure, and the higher the importance of blowdown.

So, the most

critical rpm area for this is the upper powerband area (where the pressure in

cylinders at transfer opening is at the greatest).

We have

probably all seen the color of the transfer ducts, and even the crankcase area

and sometimes also the inlet duct, when pulling a cylinder after it has been on

the bike for a while: It’s black-ish

carbon deposits from combustion, due to insufficient blowdown. Exhaust gases

literally flow down transfers. We want to reduce this, and that’s why modern strokers have big aux ex ports.

Sadly, we cannot make such ports in our triples, there

is simply no room due to the studs.

So, we have to make the best we can out of the stock single port, and luckily, Kawa was conservative regarding that port. It only has a 43mm width, and a quite rounded upper part. By using Wossners and Wisecos where the piston ring gap faced rear, we can increase to close to 70%, square the port, and still be safe. That way, we can gain a lot of power.

Above is an

example of the ex port shape that I use, versus stock

port. As you can see, the blowdown area is increased significantly only by

widening the port and raising the cylinders.

As said, a

1,5mm lift gives 185-ish duration, and now improved blowdown even if blowdown

duration has DECREASED.

For more

power in upper powerband, you can raise the port further. I now use 188.

Previously I used 193. No need to go any further, as you lose power stroke the

more you raise the port, and also move powerband upwards.

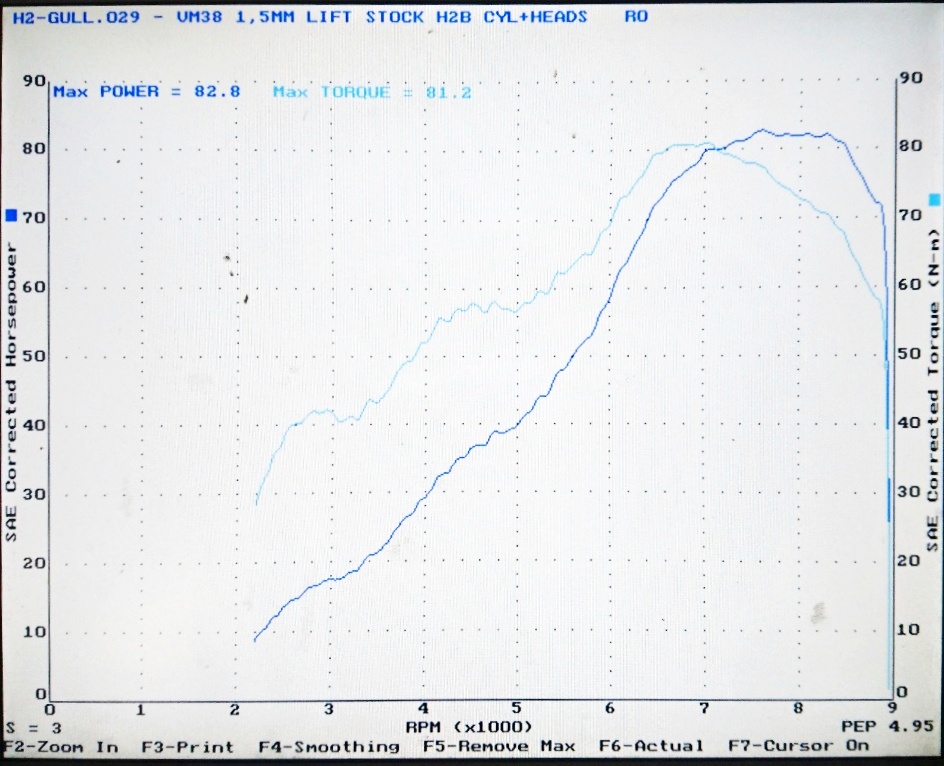

I also tried

out a set of bone stock H2B/C cylinders, raised 1,5mm and with the use of 38 carbs

and the mighty Jollymoto pipes. No blueprinting.

Removed top gasket and used high temp silicone based gasket instead. I reached

90 rwhp. By doing the port layout as seen above, you can pass the 100 rwhp

target.

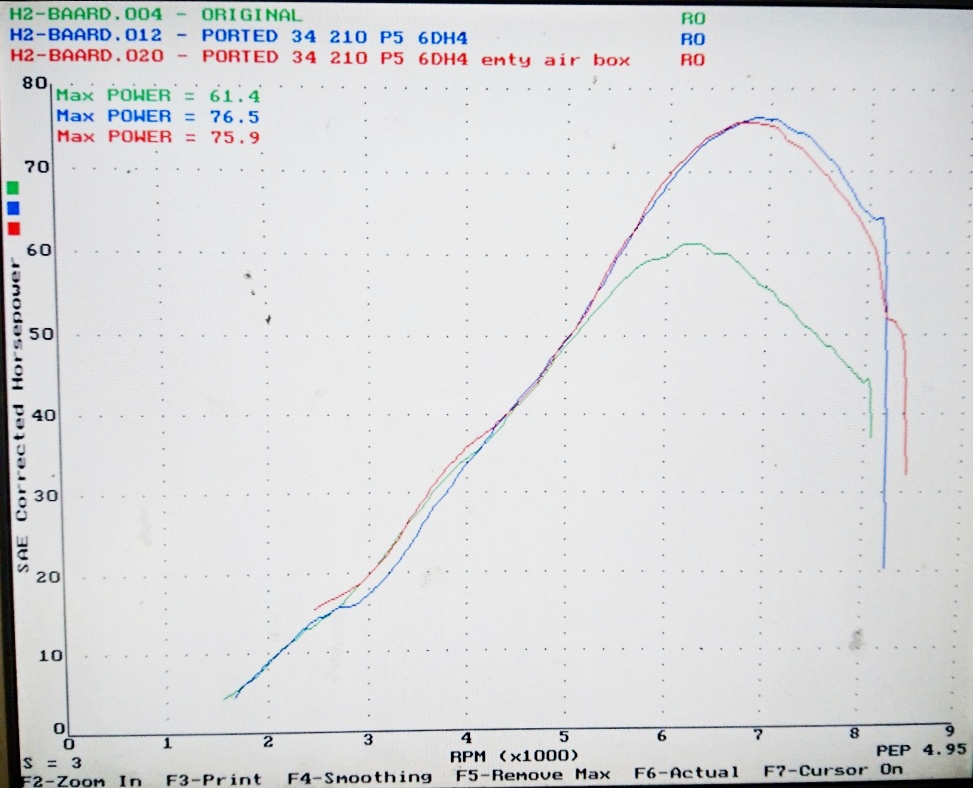

Above is a dyno test with blueprinted cylinders with the ex

shape shown earlier. But this one has a 0,5mm lift, and only a 0,5mm additional

lift of exhaust port, with VM34’s. As you can see from the stock green line,

the power starts flattening out at 5300 rpm due to the insufficient blowdown

and tiny carbs. So, just by doing what I said, you can increase power more than

25% WITHOUT losing low end (this is with VM34 sledge carbs where you can use

stock air box, with only a mesh filter on top of box (red line). Blue line is

with the use of Ramair pods.

This is about same peak power as you can get by adding 34’s and denco pipes to a set of stock cylinders… 75-ish rwhp.

This is early square cut cylinders by the way, before and after portwork.

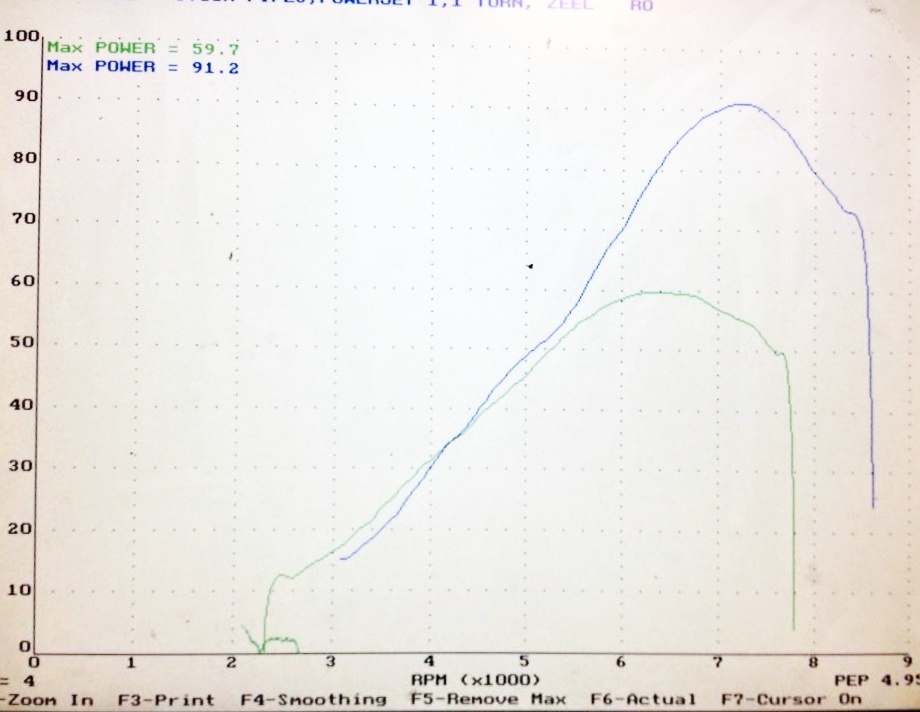

Above is what is achievable when TMX39,2 mm carbs are used, SSO Billet heads, ported crankcase, modified inlet window, modified transfer ducts and dividers, modified transfer windows for more flow and different aiming, adjustable ignition and the mighty Jollymoto pipes. Peak power using reference pipes Denco would have been about 108-110 rwhp. Around 100 with Higgspeed, and around 90 with stock pipes. So, this gives a clue how important pipes are.

All the work getting the last ponies is VERY, VERY time consuming and is NOT achievable with a Dremel tool. But you can reach 100 rwhp with ease just by putting on 38’s, raising cylinders 1,5mm, doing the 188 ex port shown earlier, deck the cylinders to a 1mm safe squish and use gasket compound as mentioned instead of stock head gasket.

My SSO heads have stock volume by the way.

Above is a stock H2 including snorkel (square cut early cylinders) versus the fully ported ones I had two years ago, using VM38 with powerjet and Aylor heads… both with stock pipes. As you see……a 100 crank hp H2 is achievable with all the mods. I guess this one would have given 85-ish without all the crankcase and transfer mods. Once again, you have good low end power even if the peak power is good. This is with adjustable iggy. (blue line only)

Above are the stock H2B/C cylinders with a 1,5mm raise ONLY, and VM38 (bored out 1mm) carbs and no head gasket, using Denco replica pipes.

This is what you get by not doing any portwork at all, except fitment for 38mm inlet rubber. A bit rich this one. With correct jetting only, and the described ex port (which anyone can do with a Dremel), removal of stock head gasket, you will probably be into the 90-ties rwhp with ease.

Yes…..it is that easy.

No….I did not compensate cylinder lift regarding inlet duration. So, inlet duration is 1,5mm LESS than stock.

But you will gain a lot by decking cylinders and adding squished band heads.

This is with stock iggy.

More 2 stroke tech to come, but you can also have a look into this thread were much of it is explained: Link

Best regards