Bulletin#: 73 H-16

Date: Oct. 20, 1972

Bike(s) affected: H1, H2

Subject: Oil pump modification

Action taken:

PROBLEM: There is a tendency for some three cylinder models to smoke

excessively from one exhaust pipe. On the H1 and H2, it is usually the right

cylinder that is affected.

CAUSE: This problem has been traced to faulty O-ring seating in the oil pump

end cover. After installation, the two O-rings inside the cover shrink

approximately .1 to .2mm in diameter. This shrinkage allows oil to seep

around the seals and into the end cover chamber. From this point, the excess

oil is pumped to the right cylinder which is serviced by the end cover

orifice, resulting in smoking and premature spark plug failure.

It should be noted that other symptoms may indicate oil pump malfunction,

such as right hand piston seizure. This may be caused by oil being forced

back into the main pump body through defective O-rings. As a result, the

right cylinder is starved for oil, and this situation will eventually lead

to seizing.

CURE: To remedy this problem, the oil pump end cover has been redesigned to

prevent oil seepage.

A. The radius in the end of the cover has been decreased in depth to give

the O-rings less "squish" space.

B. The bottom radius has been eliminated.

C. The internal diameter of the chamber has been decreased from 14.0±.1mm to

13.7±.05mm to compensate for shrinkage.

D. A slight shoulder has been added to the chamber base to further compress

O-ring.

A conversion kit is available to correct older model oil pumps. The kit

consists of two mounting screws, two O-rings, and a new oil pump end cover.

These parts will fit all three cylinder oil pumps. Conversion kit P/N

99990-016. IMPORTANT: Whenever an oil pump is disassembled for any reason,

the O-rings must be replaced. The end cover O-rings are P/N 16090-002.

----------------------------

This issue wasn't about diameter of the O ring as much as it was about the

"crush" distance of the O ring between the oil pump body sealing surface,

and end cap sealing surface

This was/is a common problem with the H and S series pumps. The sealing O

rings on the output cap end of the pump get "sacked" (make themselves into

an oval, and decrease in overall diameter, and allow pumped oil to migrate

back into the pump chamber, away from the output port. What the factory did,

in effect, was to devise a revised replacement end cover and send new O

rings with it, in a kit listed by p/n above. The revised cover literally had

a smaller area and profile that would not allow the O ring to become

compressed, eliminating the back leak form the outlet port to the pump

chamber. This restored correct oil metering to the right cylinder, if I

remember which one it was correctly, from memory.

What all this means is, the end cover was trimmed down and the radius inside

it reduced, to hold the O ring in more tension, and not allow it to change

shape and leak. This can be done to early non-modified end caps as well,

simply trim about 0.80 to 1.00mm (appx. .032 to .040 inch) off the mating

surface of the end cap, and install a new O ring, should work as well as the

factory modified cover, and clear up the problem/issue. I used to cut the

end cap on a lathe, but, since than, I have made a fixture for my milling

machine that holds the cap with the sealing end upwards, and plunge cut the

end of the cap with a mill boring tool/index head. Sounds complicated, and

care MUST be used to get the cut right, so the end cap/O ring seals

correctly, but it isn't rocket science/brain surgery.

DO NOT MODIFY THE OIL PUMP BODY, NOR THE GREEN ANODIZED PISTON GUIDE SLEEVE

INSIDE IT, THEY ARE NOT THE PROBLEM.

A very crude visual example of what happens is such:

Take your index finger and thumb, and make a circle of them, THIS is what

the O ring looks like new. To replicate what the O ring does, extend both

that index finger and thumb, and move them straight out from your palm,

parallel with each other, spaced apart, creating two flats of the

finger/thumb. Both flats are what happens to the O ring, becomes flat on the

sealing sides (body to cap), reducing the sealing tension on the O ring,

allowing the leak. The modded cover simply puts more "squish/crush tension"

onto the O ring itself.

I haven't modded a pump end cap for years, but if memory serves me right,

and that is very dicey, the O ring is a pantogram, isn't a simple O ring, it

is a mounded to fit the odd shape ring.

If you use a shim to compress the O ring further, the shim would sit against

the metal, and being metal, wouldn't seal, UNLESS you ran two O rings, and

built the pack oil pump body - O ring - shim - O ring - end cap.

Just something to think about, and check out as well.

From my now feeble mind's "memory", the change in the end cap was something

like the depth from the sealing surface to the end of the guide sleeve area bore

in the cap, was reduced from 18mm, down to 16mm, but, I could be wrong. This

would compress the one O ring between the body and end cap another 2mm's or so,

for a better O ring compression and seal.

I don't see any reason against using the significantly better O rings available

today in these pumps. Better materials are now available. I don't see why the

factory didn't make the one flat compression ring a square cross section,

instead of an O design.

That aluminum thing with all the holes sticking out the rear of the main pump

body is called a "guide sleeve", and SHOULDN'T turn in the main body. That small

piece of metal could be the pin that inserts into the guide sleeve, and the

body, to stop the sleeve from turning in the body.

That sleeve has openings that MUST align with the delivery and fill holes in the

oil pump body, and if the sleeve turns free in the body, the holes can close

off, stopping oiling to the engine.

The guide sleeve IS NOT the green anodized piston in the ehter of the guide

sleeve.

The reason we need to seal the end cavity off well is, if there is a leak, it is

on the pressurized delivery side of the end cavity, which allows pumped oil to

migrate back into the pump cavity, and NOT be delivered to the cavity and oil

line. Reduced oil volume is the result, with engine damage possible.

Barry wrote:

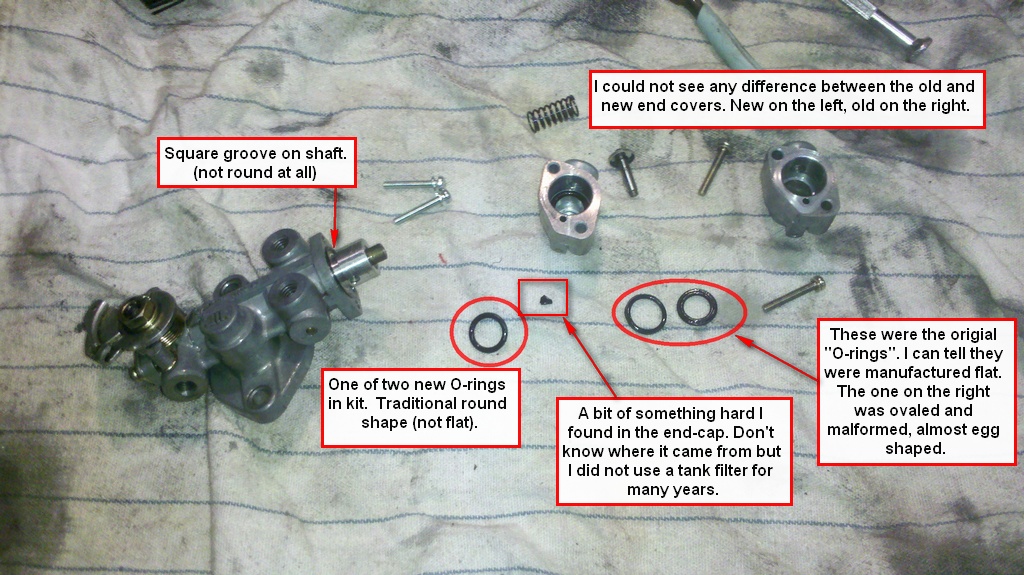

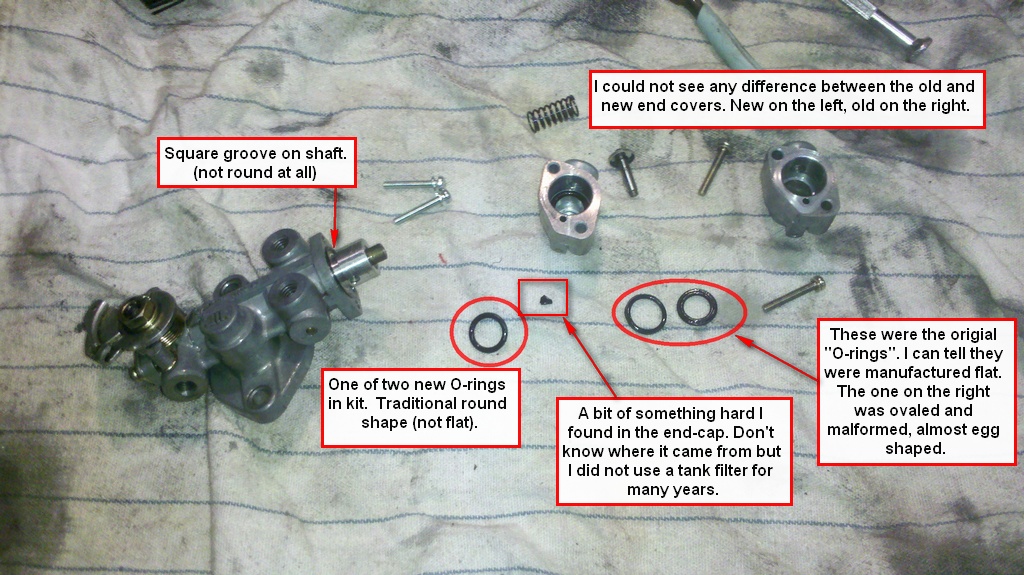

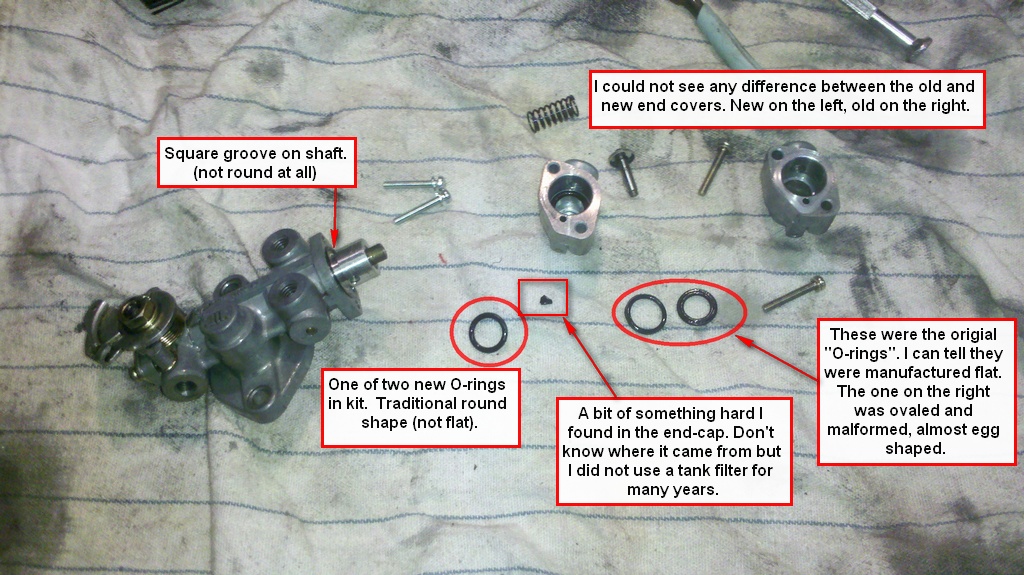

I got around to installing mine today. I did not see any size or shape

differences between the old cap or the new. I did notice the old "o-rings" were

definitely flat where the two new ones were round/traditional shape. I assume

one of the new ones went on the inside of the shaft (where I note it's square)

and the other was on the end of the shaft where it seats into the cover.

Ironically the inside one I took out was the malformed one, I would have thought

the end one would get squished, interesting.

Also not the bit of junk I found inside, a note for anyone NOT using a tank

screen.